The Benefits of Using a Tyre Shredder in Recycling

Tyre waste has turned into a substantial environmental matter as a result of rapid development of the automotive business and the increasing quantity of end-of-life tyres. Large-scale procedures dealing with tyre recycling involve particular machinery capable of effectively managing high sizes of tyres. tyre shredder equipment was created to match these needs, supplying a reliable and sustainable option for tyre disposal and recycling.

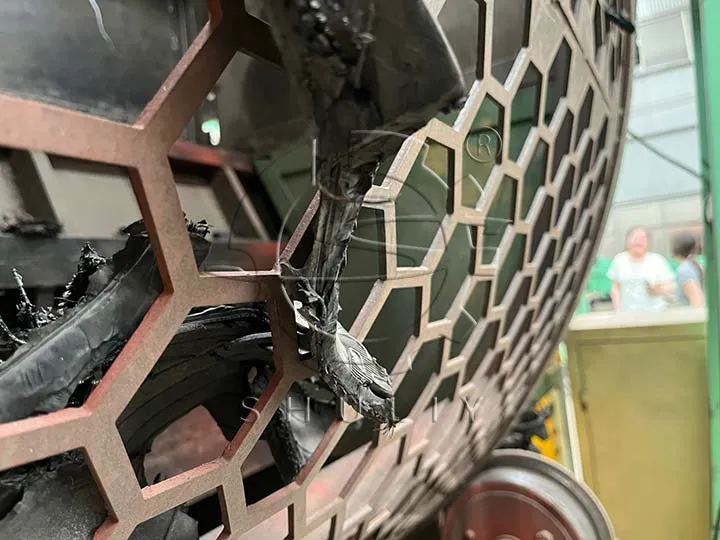

Contemporary tyre shredder equipment will come in numerous designs, including main, secondary, and granulator shredders, each helping a particular function in the recycling process. Main shredders are used to break down whole tyres in to feasible pieces, while extra shredders lower these parts into smaller granules or chips suitable for more processing. Granulators are used to create standard rubber particles which can be recycled in manufacturing plastic rugs, playground areas, or as gas in cement kilns.

Among the essential top features of tyre shredder gear for large-scale operations is its high capacity. These models are made to deal with hundreds of tyres per hour, ensuring continuous operation and minimizing downtime. Heavy-duty knives and robust generator programs permit them to reduce through solid rubber and steel-reinforced tyres efficiently. Sophisticated versions also contain magnetic separators to acquire material cables, making the productivity solution and more flexible for professional applications.

Safety and detailed effectiveness are other important facets of large-scale tyre shredders. Modern gear usually contains automated eating methods, hydraulic regulates, and emergency stop mechanisms to lessen handbook managing and improve agent safety. Additionally, energy-efficient engines and enhanced chopping elements reduce working prices while sustaining high performance.

Large-scale tyre shredding procedures not merely offer an eco-friendly way to dispose of end-of-life tyres but also create financial opportunities. Recycled rubber can be converted into crumb plastic, used in asphalt, floor, and sports surfaces, or prepared more for pyrolysis to make fuel gas, carbon dark, and steel. By implementing tyre shredder equipment, corporations can contribute to sustainable spend administration while benefiting from the professional price of recycled materials.

In summary, tyre shredder gear is vital for large-scale recycling operations, providing efficiency, security, and versatility. The right machinery ensures high throughput, consistent result quality, and paid down environmental impact, which makes it an important expense for tyre recycling facilities. With the rising demand for sustainable answers, adopting advanced tyre shredding engineering permits companies to turn spend in to important resources, promoting both environmental obligation and financial growth.